Improving Injection Molded Designs with 3D Printing

One of the most valuable aspects of 3D printing is the ability to iterate and improve on existing designs. Any time a client needs our help with reverse engineering a part to 3D print, we always ask them if they have any ideas for how it can be improved. Sometimes the answer is “no–the OEM knew exactly what they were doing”, but most of the time our clients have a thing or two that they’d like to test out and/or change.

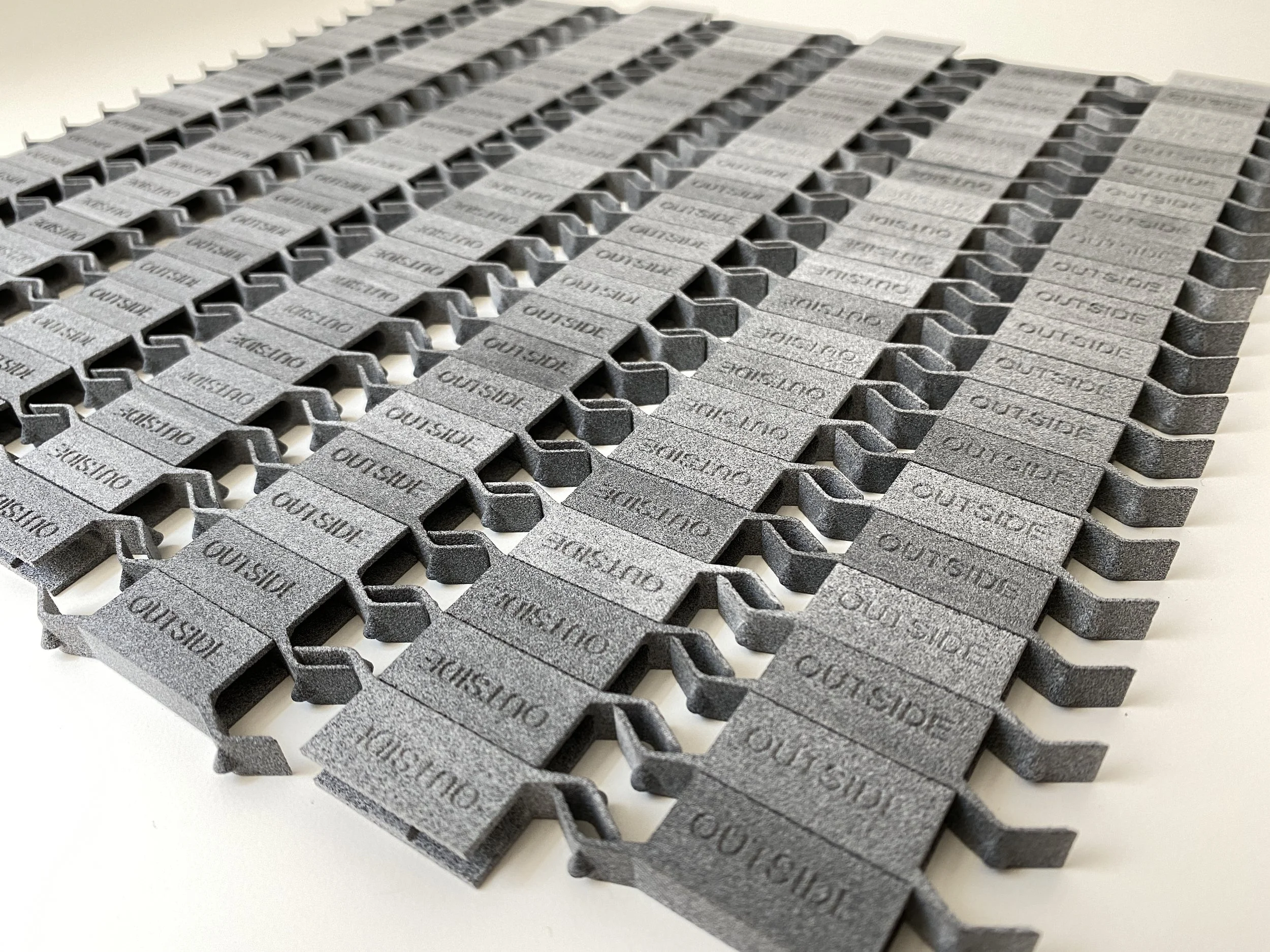

Recently, a client came to us wanting to reverse engineer an automotive trim clip for certain models of classic cars. The original injection molded parts are no longer being produced yet there are still car enthusiasts that need them for restoration purposes. Our client had several ideas for how the part could be improved, all of which we tested through rapid prototyping. Some of these ideas didn’t actually improve the part as hoped, but others did and were all incorporated into the final design.

Left: Improved 3D printed automotive part; right: Original injection molded automotive part

Not only were we able to improve the design of the part, we were also able to use a more durable material. The original part was made out of ABS plastic which snapped easily at the 90 degree corners. The updated part is printed in PA12 nylon on an HP 3D Printing MJF printer that produces durable lightweight parts that require much more force to break.

The first low-volume production run of the parts took place last week and the first batch are already being installed into vehicles around the world. Should our client decide to update the design further, we will be able to easily edit the CAD file using Autodesk software prior to printing the next batch. The flexibility that 3D printing offers is unparalleled in the manufacturing industry.