The Ultimate Guide To The Most Popular 3D Printing File Types

Before you can “press print” on a 3D printer, you must first have a digital 3D model of your part(s). 3D models can come in a variety of CAD file types that can be opened and edited in 3D modeling software such as SolidWorks, Fusion360, Blender, Rhino, Maya, as well as many others (some of which are free). Creating these models can require 3D scanning, reverse-engineering, or hand-modeling from scratch depending on the part, but once the model is completed, you can use it over-and-over again to print. You can also easily make changes to a digital 3D model–a significant manufacturing benefit when compared to injection molding to 3D printing.

One of the most common discussions we have with clients is what types of 3D model files we need for quoting and 3D printing parts. The answer is that we have a strong order of preference, but we can make-do with most file formats. Below are the file types we work with from our most preferred to least, you can upload any of them on our website to start your 3D printing quote process. If you don’t have a 3D model created yet, we can also help you turn your idea into one!

3D Model File Types for 3D Printing

STL

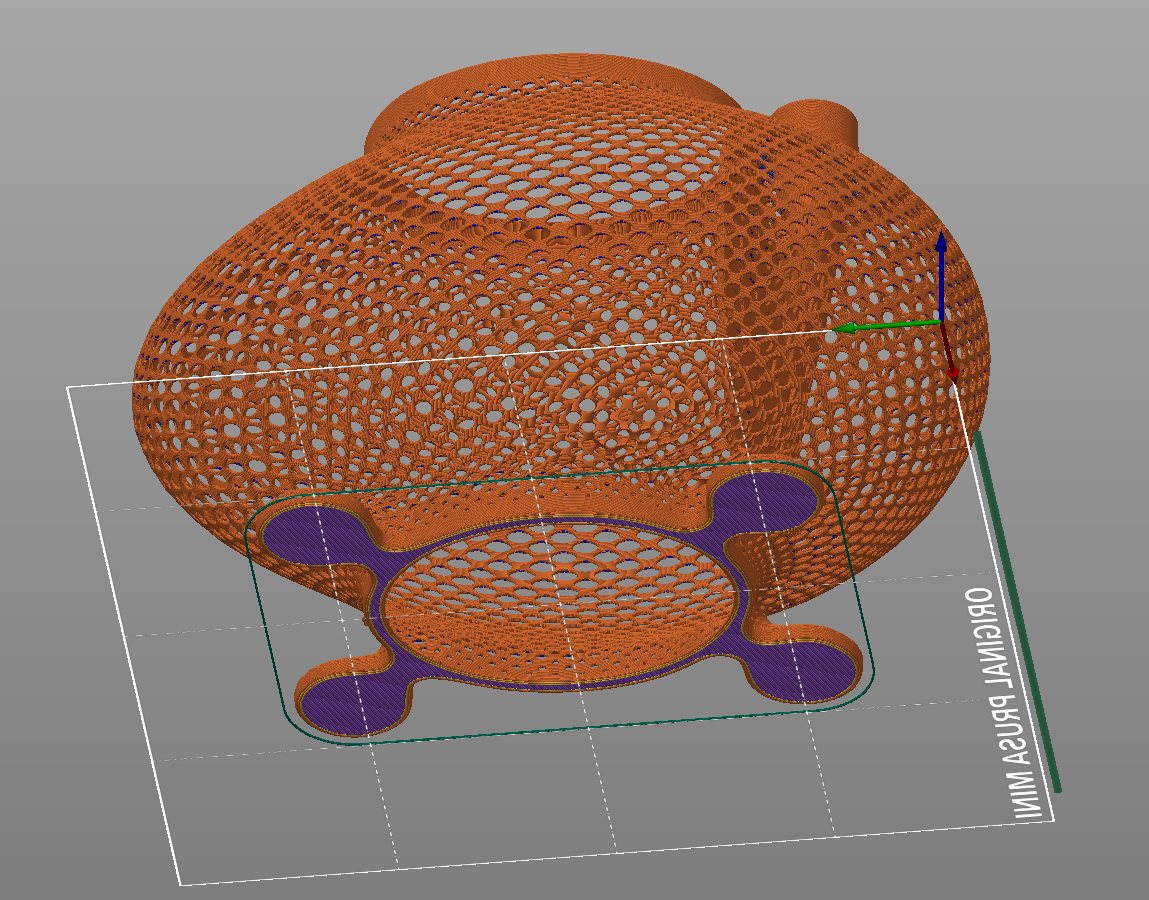

The most popular file format for 3D printing is .stl. This file type uses STL (Standard Tessellation Language) to create a mesh of triangles to define surfaces. It is the industry standard file type and allows users to create files in a variety of shapes and sizes. The files tend to be smaller and simpler than some of the other formats, making them easier to open, edit, and share. STL files can be found for free on various websites such as GRABCAD, Cults3d, CGTrader, Yeggi, and Thingiverse, and help make 3D printing more accessible and open-source for everyone.

We prefer STLs because they can be easily opened and edited in the 3D modeling software that we use. Our team is proficient in creating 3D printable STL models for a variety of different 3D printing processes and materials such as FDM / FFF, SLA, SLS, MJF, SLM, DMLS, and binder-jetting. If you send us an STL, we know we’re off to the races.

OBJ

The second most popular file type is .obj. An OBJ file is a more complex format than STL because they contain more data about the part, such as its texture and color. They are designed specifically for 3D printing and tend to have higher resolutions than STLs. While this additional data may make it easier to see what the finished product looks like, it’s not always necessary and can possibly slow down the process. OBJ files are necessary when printing a part in full-color and may be accompanied by MTL (Material Library) or VRML files that hold additional data such as color and texture.

If someone sends us an OBJ file, we can almost always work with it. However, most of the time we will convert OBJ files to STL files for ease of use. If your project requires an OBJ file, we have the software and expertise to manipulate the files as needed and ensure that your parts are printed properly.

STEP / STP

There is certainly nothing wrong with a .STEP (Standard for the Exchange of Product Data) or .STP file in general, they are extremely useful for professionals who need to include lots of data and information about their parts in one file. Hence why they tend to be popular output from engineers, industrial designers, and product designers. They’re ideal for projects that involve iteration or design changes post-download. For the purposes of 3D printing they can be cumbersome to prepare for printing since the files often contain so much information that they’re difficult to download or open.

When we receive STEP files for printing, we almost always immediately convert them into STL files to make them a more manageable size. We have software that can open them, but we don’t prefer to work in them for print setup. Most software will allow you to export 3D models as an STL rather than a STEP, if you have that option, we always appreciate it when clients do so. However, if we’re working with you on 3D designing parts, STEP may be more useful at those early pre-printing stages.

3MF

A newer file format (developed in 2015) that is growing in popularity is .3mf. 3MF is an open-source file format that was created to replace AMF files. The benefit of 3MF files is that they have the potential to eliminate a step in the 3D printing setup process. Other file formats are typically first opened in a 3D modeling software that allows them to be edited and then transferred to a slicing software where additional printing information is included into the file. 3MF files don’t necessarily need to be opened in a 3D modeling software, they can go right into the slicer to be turned into gcode that the printer recognizes.

If a client sends us a 3MF file that is ready to print, that makes our lives easier. However, it’s unlikely that the file would be set up in a way that would work perfectly for our printers. We’d likely still want to look at the file in the modeling software and review it in our slicer software before converting it to gcode. It’s exciting to see more and more people becoming familiar with slicers, and thereby 3MF files, though.

CAD File Types for 3D Design

The file types included in this article are what we work with for 3D printing, but are by no means all of the CAD and BIM files we can accept for design work. Just some of the other CAD file formats we can work with in the design stage include: JPEG, JPG, PNG, DWG, PLY, DXF, RVT, and NWD. We even accept hand-drawn sketches.